You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cams, compression, revs and power...

- Thread starter Kozy

- Start date

- Joined

- Aug 18, 2008

- Messages

- 4,076

As you say far to many people do come into this being told by internet forums and the like what parts or brand of parts they need to fit to reach certain h.p goals and there are far to many internet experts who talk the talk only for you to find out they have no real world experiance, my advice get out there and get building, change things and write down what the changes did with diffrent tunes/settings.

I don't have thousands of pounds to burn on testing engines, I don't have a dyno I can use at my lesuire and mist importantly, I don't have the time. In your eyes, that makes anything I say worthless.

The way I look at it, if I looks like a duck and quacks like a duck, then it's probably a duck, and in the same vain if the numbers don't stack up on a particular combination of parts then I feel fairly confident that they will not work the way I intended. I had a build planned for my blown b16b, and having seen a few similar, knew it was pretty likely to work exactly how I planned, but guess what, I ran out of money and I ran out of time! I still have that block in the garage, so maybe it will get built one day, and if it doesn't work then I'll be honest, raise my hand and say I got it wrong.

In the meantime, I'll continue to model and simulate the workings of a car in order to understand it. You think there is no value in this and that's fine, but a large proportion of the motorsport industry would disagree with you.

- Joined

- Aug 18, 2008

- Messages

- 4,076

http://www.ek9.org/forum/resource-a...-specs-comparison-honda-b-series-engines.html this is an excellent read, that explains a lot, and shows that it`s not black and white when it comes to camshafts.

A great source of reference that has been! Needs updating though I reckon...

Most people when speaking about power an engine made have in mind peak power. Though one might see a +5hp peak but gains 5K-8K could be well over 30-40hp ans significant increase in torque.

If this is the case, then fair enough! If people are happy with what they have then that is the most important thing.

rs250nut

Boosting since 1998

- Joined

- Feb 14, 2011

- Messages

- 598

I don't have thousands of pounds to burn on testing engines, I don't have a dyno I can use at my lesuire and mist importantly, I don't have the time. In your eyes, that makes anything I say worthless.

The way I look at it, if I looks like a duck and quacks like a duck, then it's probably a duck, and in the same vain if the numbers don't stack up on a particular combination of parts then I feel fairly confident that they will not work the way I intended. I had a build planned for my blown b16b, and having seen a few similar, knew it was pretty likely to work exactly how I planned, but guess what, I ran out of money and I ran out of time! I still have that block in the garage, so maybe it will get built one day, and if it doesn't work then I'll be honest, raise my hand and say I got it wrong.

In the meantime, I'll continue to model and simulate the workings of a car in order to understand it. You think there is no value in this and that's fine, but a large proportion of the motorsport industry would disagree with you.

You dont need thousands of pounds, you dont need a dyno and last but not least you need to make time, my engine has been in the process of being built in my garage for the last eighteen months but I still do bits on it here and there.

Chill with the negative vibe, im not disagreeing with you just mearley putting my point across, like I have said for the third time theory is all well and good i.e you need to do a certian amount BUT the proof is in the pudding. My old r5gtt was good enough for thirteen second quarters on road tyres and the whole engine, gearbox,clutch etc cost me no more than £1500 and never saw a dyno as I believe and so do many others than you cant beat real world mapping/ tuning. This was all done just by messing around with parts, taking bits from here and there, recording what happened good or bad I still wrote it down, I had a very basic wideband set up and a pair of det cans to listen for knock when spanking it up the dual carriageway not on the dyno.

Where did I write that I thought there was no Value in research? I wrote this first and you attempted to shoot me down, again

My post was not meant to be negative in anyway shape or form bud just adding my 2 pennys. THEORY IS ALL WELL AND GOOD but sometimes you just have to get on and try it.

This thread started out good but again you feel the need to try and discredit what I have said like you did in the spoon thread, yet again you failed, good bye im done with this school yard bullshit.

pateras_vtec

Active Member

- Joined

- Feb 16, 2008

- Messages

- 1,337

For those still interested in the original topic.

What are the benefits of over compressing an engine?

What are the downsides?

Over compressing doesn`t sound right to me. Big compression is what many people use to get the most out of high lift long duration cams. besides wear on the valvetrain and pistons, low to mid range losses are a few of the downsides. No to mention that tuning is not as easy with a lower CR engine. And if you`re using pistons that have an Λ dome that devides the combustion chamber in two which is very bad for burning the mixture.

- Joined

- Jan 29, 2008

- Messages

- 6,259

Just my 2 penny's worth

My car idles perfectly at 1100-1200rpm perfect! Pull all the way from this rev very cleanly with no flat spots or loss of power. I gained everywhere from my build. Ok didn't reach the numbers I was quoted but still made a healthy 30-40whp everywhere over my stock b18c.

It drive perfectly smooth on the road and is very easy to drive (apart from the diff) on track it's even better!

13:2.1 SCR

Toda C cams

Just my 2 pence.

Still reading intently

My car idles perfectly at 1100-1200rpm perfect! Pull all the way from this rev very cleanly with no flat spots or loss of power. I gained everywhere from my build. Ok didn't reach the numbers I was quoted but still made a healthy 30-40whp everywhere over my stock b18c.

It drive perfectly smooth on the road and is very easy to drive (apart from the diff) on track it's even better!

13:2.1 SCR

Toda C cams

Just my 2 pence.

Still reading intently

- Joined

- Jun 5, 2007

- Messages

- 6,214

low to mid range losses are a few of the downsides.

There doesn't need to be any downsides. Many new camshafts have been developed to achieve significant low-midrange increases whilst also producing good top end power. Skunk2 Pro series cams been a good example, they offer massive midrange punch.

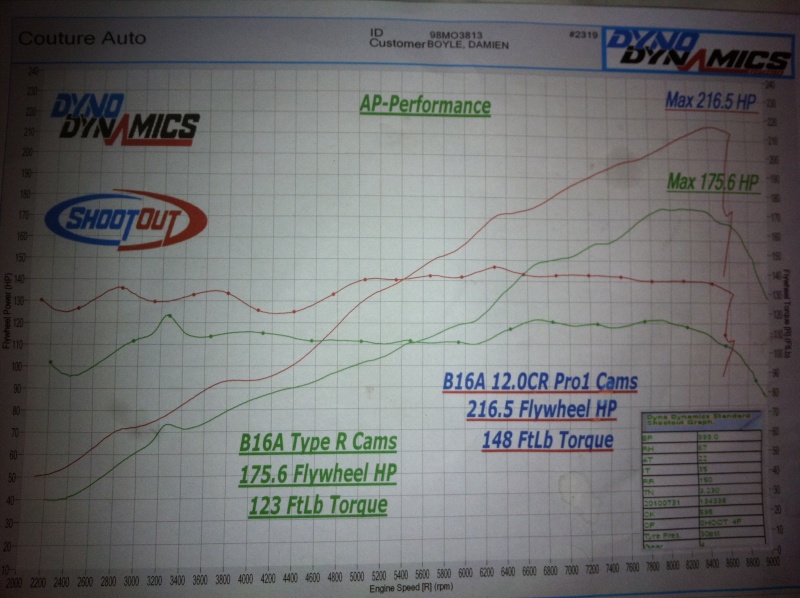

Example here of a rally car I mapped two years ago with stock engine and type r cams vs the built engine this year which consists of Wiseco 12.0:1 pistons and Skunk2 Pro series stage 1 cams. As you can see the car has picked up power everywhere with a massive increase in midrange torque and holding the torque curve very well up top.

- Joined

- Jan 4, 2009

- Messages

- 5,094

Nice graph there vtec6000 like you say clearly shows very nice tourque across the rev range. from 4400 onwards just like you said there is massive mid range punch... what sort of power would 216 bhp be at the wheels... is there a rough conversion ?? good power for a b16A..

still enjoying this thread guys...

Rs250Nut - please don't stop commenting on this thread i ahve enjoyed reading everything you have written.. and also watched those videos last night with a couple of beers ( didn't go out lol ) but i kept pausing it and bringing up wikipedia and google to search certain things they mentioned.. i honestly learnt LOADS from the videos..

ANyway i am learning from what you and others say so please don't stop your comments.. someone like me for instance is loosing out from the knowledge you bring to the table..

The internet is the perfect place for meesages to get lost in translation so maybe kozy didn't mean to come across that way after all he took what you said the wrong way so it shows things can come across the opposite way they were intended on the internet..

so yeah dude please continue with adding to this thread..

still enjoying this thread guys...

Rs250Nut - please don't stop commenting on this thread i ahve enjoyed reading everything you have written.. and also watched those videos last night with a couple of beers ( didn't go out lol ) but i kept pausing it and bringing up wikipedia and google to search certain things they mentioned.. i honestly learnt LOADS from the videos..

ANyway i am learning from what you and others say so please don't stop your comments.. someone like me for instance is loosing out from the knowledge you bring to the table..

The internet is the perfect place for meesages to get lost in translation so maybe kozy didn't mean to come across that way after all he took what you said the wrong way so it shows things can come across the opposite way they were intended on the internet..

so yeah dude please continue with adding to this thread..

- Joined

- Jan 4, 2009

- Messages

- 5,094

Grab some beers for it dude its a great video.. nice old trip back to the 80's lol.

watch part 2 also mate, i properly enjoyed it.

watch part 2 also mate, i properly enjoyed it.

- Joined

- Jun 5, 2007

- Messages

- 6,214

Nice graph there vtec6000 like you say clearly shows very nice tourque across the rev range. from 4400 onwards just like you said there is massive mid range punch... what sort of power would 216 bhp be at the wheels... is there a rough conversion ?? good power for a b16A..

Would be about 181whp, it's roughly 16-17% from whp to bhp.

Rich777

Active Member

- Joined

- Sep 27, 2007

- Messages

- 3,656

For those still interested in the original topic.

What are the benefits of over compressing an engine?

What are the downsides?

There is no benefit in over compressing a engine. Raising the compression ratio demands a higher octane fuel and also decreases the mechanical efficiency of the engine (eventually).

Basically when tuning ignition timing (for a NA setup/some FI) you want to keep adding ignition timing untill your reach MBT (maximum brake torque). After MBT providing the octane rating of the fuel is sufficient enough you can keep adding timing and the engine won't make anymore power (it will most likely start to drop off). When the engine is "over compressed" and the octane rating of the fuel isnt sufficient enough you will hit knock/det before reaching MBT. This will cost you power unless a higher octane fuel is used, the combustion chamber and ports are redesigned (quench, less swirl) or

the cam timing is retarded to promote reversion intake/exhaust reversion.

Mechanical efficiency is basically the energy used to compress that extra cylinder pressure & the extra friction i.e. from the piston rings been pushed against the cylinder walls on the compression stroke (note: higher compression engines do wear piston rings out quicker compared to low).

As for these flat spots people tend to get. Well i agree with RS250NUT, a lot of it is "trial and error". If your lacking power somewhere in the power band and its somewhere what you'd like to pick up then experimenting with parts needs to be done. I think once you've got your good "base engine" with proven parts, then it just comes down to having a play with the intake, exhaust & cam timing side of things to try and pick up whats down. In Ian's case i think his manifold is a bit restricted in high rpm and not really made to suit his setup. A better flowing manifold with good cylinder scavenging capabilities should go along way (i've actually seen it on a similar setup).

- Joined

- Jan 4, 2009

- Messages

- 5,094

Would be about 181whp, it's roughly 16-17% from whp to bhp.

thanks dude.. is that pretty much across the board for Ek chassis civic's or FWD cars in general.

- Joined

- Aug 18, 2008

- Messages

- 4,076

Rich is on the money as always, acheiving MBT is the goal here. An engine running at MBT will be crisp, responsive and powerful, one running retarded will make less power as peak cylinder pressures becomes lower, EGTs rise, engine response slows and the engine note dulls.

MBT is dependant on the cylinder pressure at ignition, which in turn is highly dependant on the compression ratio and volumetric effeciency. We can usually expect the effect of compression ratio to be constant throughout the engines operational range, however the volumetric effeciency is always on the change, usually in an upward trend as engine speed increases. If the cylinder pressures are too high at the point of ignition, the charge will detonate instead of burn, and this becomes the knock limit for a particular setup and fuel. Hitting the knock limit before MBT means we are throwing away potential power as we have to retard the timing from MBT. Less torque, worse response, a rise of EGTs.

So, extreme compression ratios, long duration cams, cylinder pressures and MBT. I am seeing a conflict on interests as the revs go up here...

MBT is dependant on the cylinder pressure at ignition, which in turn is highly dependant on the compression ratio and volumetric effeciency. We can usually expect the effect of compression ratio to be constant throughout the engines operational range, however the volumetric effeciency is always on the change, usually in an upward trend as engine speed increases. If the cylinder pressures are too high at the point of ignition, the charge will detonate instead of burn, and this becomes the knock limit for a particular setup and fuel. Hitting the knock limit before MBT means we are throwing away potential power as we have to retard the timing from MBT. Less torque, worse response, a rise of EGTs.

So, extreme compression ratios, long duration cams, cylinder pressures and MBT. I am seeing a conflict on interests as the revs go up here...

b2theenneh

Member

- Joined

- Aug 25, 2011

- Messages

- 194

Loving the thread, although I have not got the money and neither the car to do this sort of stuff with to find out it's hopefully something I may touch upon at college if I decided to do Motorsport.

It really interest's me and I enjoy reading it, just a shame that I can't get my head around it yet. Maybe this time away from College in the holidays hasn't helped.

Keep it up please, love to keep reading this.

It really interest's me and I enjoy reading it, just a shame that I can't get my head around it yet. Maybe this time away from College in the holidays hasn't helped.

Keep it up please, love to keep reading this.

- Joined

- Aug 18, 2008

- Messages

- 4,076

OK lets look at it another way, since I seem to have drawn a bit of a blank.

The stock B18C:

Capacity - 1797cc

SCR - 11.32

Intake duration - 243°

Lobe centre - 103.5°

IVC - 45° ABDC

This translates into:

Effective stroke - 77.92mm

Effective displacement - 1606cc

DCR - 10.22

Cranking pressure - 239psi

VP index - 115lbft*

Now lets have a look at what Toda Cs do to those numbers. (I'm not picking on your build Ian, it's just the one that cropped up! )

)

Capacity - 1797cc

SCR - 11.32

Intake duration - 255°

Lobe centre - 103.5°

IVC - 51° ABDC

This translates into:

Effective stroke - 75.27mm

Effective displacement - 1551cc

DCR - 9.91

Cranking pressure - 230psi

VP index - 108lbft*

* V/P index is a relationship between effective capacity and dynamic compression ratio to compare the effects of changes on engine torque. While the DCR on two setups may be the same, the fact you are compressing less physical charge on one with a later IVC will mean you are still making less torque. The VPI is useless on its own as it is not a prediction of actual torque produced.

So how do the Todas stack up against the stock cams? We have 55cc less effective displacement, 9psi less cranking pressure and 7lbft less VPI. Proportionately that is 3.6% down on capacity, 3.9% down on cranking pressure combining to form -6.5% on VPI. Interestingly (perhaps), the DCR is still higher than the stock B16B's 9.66...

Now, I can't speculate how much of an effect this will actually have on the low end performance of a stock B18C with Toda Cs as there is quite clearly far too many other variables to take into account, (not least the actual degree specs of the cams which Toda seem to keep quite secret), but it doesn't appear to be as gutless as people would have you imagine. Sure, it'll be a bit weaker, but that's to be expected.

So, if you wanted stock performance before they 'came on cam' how much compression would you need to return the VPI to stock? According to my workings, an increase of just .68 to 12.0:1 would do it.

I have all the sums for figuring this bollocks out, if anyone wants them to check the numbers themselves I'm willing to share them.

Again, it's only a bit of theory intended to provoke a bit of thought about basic engine dynamics. I'm not out to offend or prove anyone/thing wrong so don't get your knickers in a twist if you're the suck-it-and-see type...

The stock B18C:

Capacity - 1797cc

SCR - 11.32

Intake duration - 243°

Lobe centre - 103.5°

IVC - 45° ABDC

This translates into:

Effective stroke - 77.92mm

Effective displacement - 1606cc

DCR - 10.22

Cranking pressure - 239psi

VP index - 115lbft*

Now lets have a look at what Toda Cs do to those numbers. (I'm not picking on your build Ian, it's just the one that cropped up!

Capacity - 1797cc

SCR - 11.32

Intake duration - 255°

Lobe centre - 103.5°

IVC - 51° ABDC

This translates into:

Effective stroke - 75.27mm

Effective displacement - 1551cc

DCR - 9.91

Cranking pressure - 230psi

VP index - 108lbft*

* V/P index is a relationship between effective capacity and dynamic compression ratio to compare the effects of changes on engine torque. While the DCR on two setups may be the same, the fact you are compressing less physical charge on one with a later IVC will mean you are still making less torque. The VPI is useless on its own as it is not a prediction of actual torque produced.

So how do the Todas stack up against the stock cams? We have 55cc less effective displacement, 9psi less cranking pressure and 7lbft less VPI. Proportionately that is 3.6% down on capacity, 3.9% down on cranking pressure combining to form -6.5% on VPI. Interestingly (perhaps), the DCR is still higher than the stock B16B's 9.66...

Now, I can't speculate how much of an effect this will actually have on the low end performance of a stock B18C with Toda Cs as there is quite clearly far too many other variables to take into account, (not least the actual degree specs of the cams which Toda seem to keep quite secret), but it doesn't appear to be as gutless as people would have you imagine. Sure, it'll be a bit weaker, but that's to be expected.

So, if you wanted stock performance before they 'came on cam' how much compression would you need to return the VPI to stock? According to my workings, an increase of just .68 to 12.0:1 would do it.

I have all the sums for figuring this bollocks out, if anyone wants them to check the numbers themselves I'm willing to share them.

Again, it's only a bit of theory intended to provoke a bit of thought about basic engine dynamics. I'm not out to offend or prove anyone/thing wrong so don't get your knickers in a twist if you're the suck-it-and-see type...

Last edited:

- Joined

- Jul 24, 2009

- Messages

- 6,294

OK lets look at it another way, since I seem to have drawn a bit of a blank...

Rock'N! Best read here, in the last 2 years!

Thanks for starting this thread Kozy!

Rich777

Active Member

- Joined

- Sep 27, 2007

- Messages

- 3,656

Kozy, you are a GEEK ! ! (just kidding Buddy  ) I found that a interesting read.

) I found that a interesting read.

Remember though that there are times and area's that sometimes we don't actually want to be running MBT (yes i said it), specially in race use. Two reasons that come to mind. 1. We may want to run slightly retarded ignition to help keep cylinder temperatures down and the piston crown cooler i.e. to help keep us away from det under constant high load conditions. 2. There maybe a area that is causing us to wheel spin when coming out of a bend or in the wet condition. In this case datalogs would need to be recorded and ignition timing removed from those area's that cause us trouble. So we actually end up with lower power in a certain area of the powerband but a faster car (check that one out hey ? ? )

Remember though that there are times and area's that sometimes we don't actually want to be running MBT (yes i said it), specially in race use. Two reasons that come to mind. 1. We may want to run slightly retarded ignition to help keep cylinder temperatures down and the piston crown cooler i.e. to help keep us away from det under constant high load conditions. 2. There maybe a area that is causing us to wheel spin when coming out of a bend or in the wet condition. In this case datalogs would need to be recorded and ignition timing removed from those area's that cause us trouble. So we actually end up with lower power in a certain area of the powerband but a faster car (check that one out hey ? ? )

- Joined

- Aug 18, 2008

- Messages

- 4,076

Remember though that there are times and area's that sometimes we don't actually want to be running MBT

1. We may want to run slightly retarded ignition to help keep cylinder temperatures down and the piston crown cooler i.e. to help keep us away from det under constant high load conditions.

2. There maybe a area that is causing us to wheel spin when coming out of a bend or in the wet condition. In this case datalogs would need to be recorded and ignition timing removed from those area's that cause us trouble. So we actually end up with lower power in a certain area of the powerband but a faster car (check that one out hey ? ? )

Good call. Without a doubt MBT isn't needed/wanted at all times, both of those instances are good examples. They don't, so far as I can see, call for increased compression though... That would infact be a complete conflict of interests in the first case!