AH man i just found this.....

FTLRacing

its s*** hot info but i need a cup of tea and a good couple of hours to get through it.

equations always throw me and then you see a diamgram and it makes total sense.

Yes have a good read, it's interesting stuff.

As always with the stuff I do, it's very much a case of garbage in garbage out, so take it with a pinch of salt, but I have a fairly comprehensive spreadsheet that I wrote at uni than depicts this sort of stuff rather nicely.

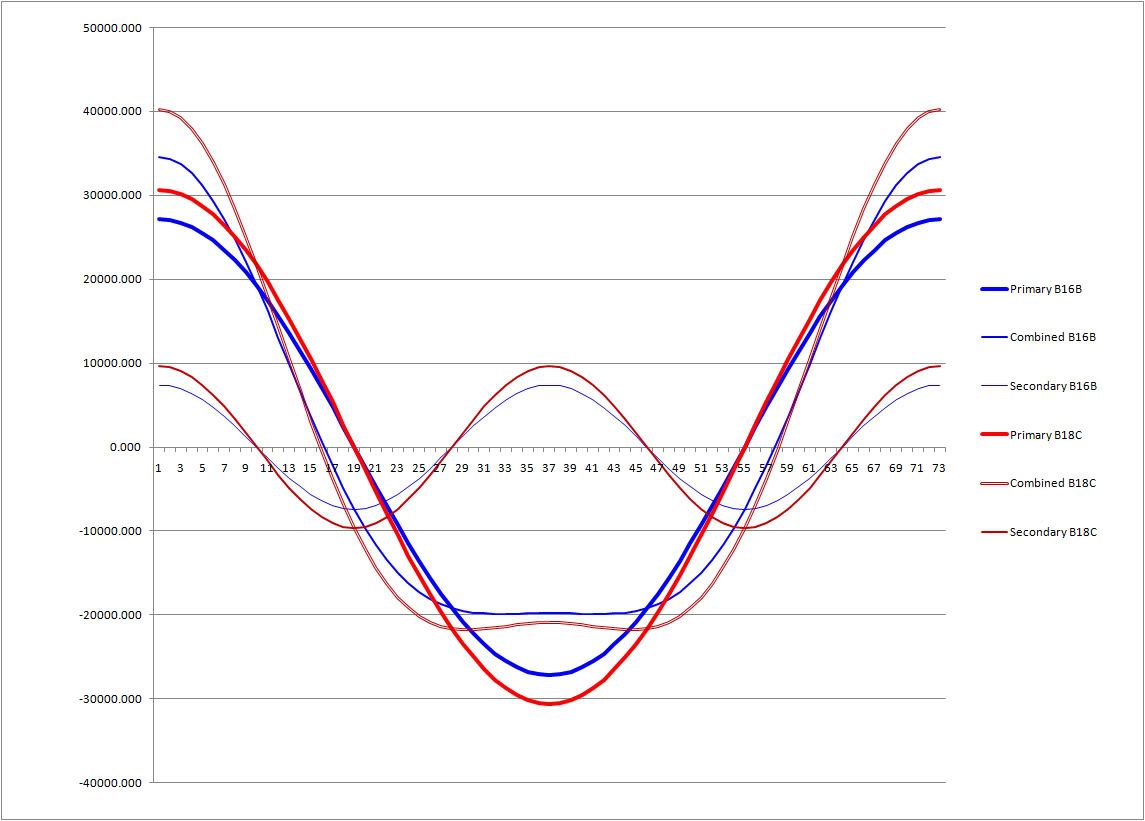

Here's a plot of the internal forces of the two engines at 8000rpm.

Primary accleration is that of the piston moving up and down the cylinder

Secondary is the additional acceleration caused by the side to side motion of the conrod.

Combined acceleration is the overall effect of the two accelerations.

We can clearly see just how much more stable the B16B is at high speed compared to the B18C. Worth noting here that the primary forces balance out in a four cylinder engine, leaving the secondary acceleration as the primary cause of engine vibration. Actually, I'm not sure it is the primary, that could be due to the firing order, but it is certainly the motion of the conrod that contributes more to vibration than the piston moving up and down the cylinder.

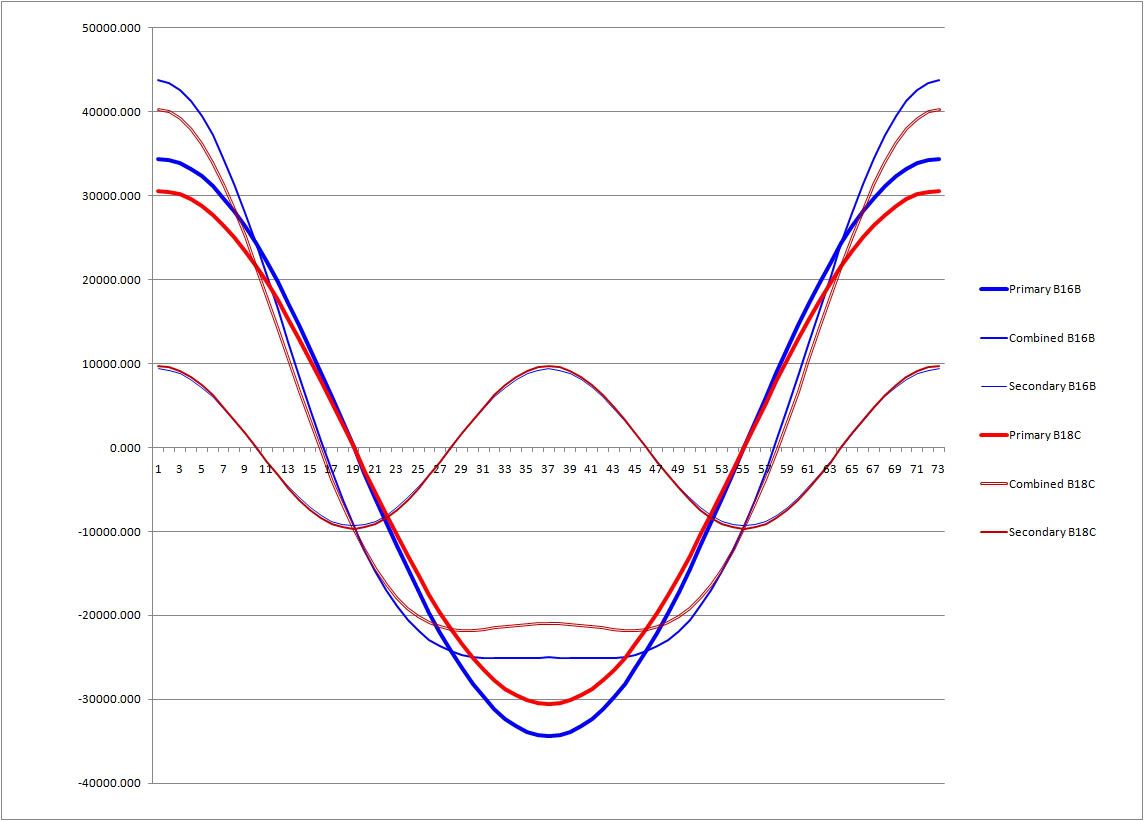

Heres the same plot with the B16B at 9000rpm and the B18C at 8000rpm.

Notice that now the primary acceleration on the B16B is higher, but since these cancel out to leave only the secondary forces unbalanced and these are now almost equal with the B18C.

Combine this with those piston speeds I mentioned earlier, and we can see how the B16B could be capable of that extra 1000rpm over the B18C. It would certainly need a bit more work to achieve this, but the possibility is there. It would need lighter pistons for a start, the B16Bs are fairly weighty at 327g compared to the B18Cs 305g.

This weight contributes to rod stretch at TDC, which then increases the compression ratio slightly at higher RPM, which then.... oh where do I stop?!

I'm going to shut up now and let someone else chat **** for a bit.