Rich777

Active Member

- Joined

- Sep 27, 2007

- Messages

- 3,660

Cheers mate.

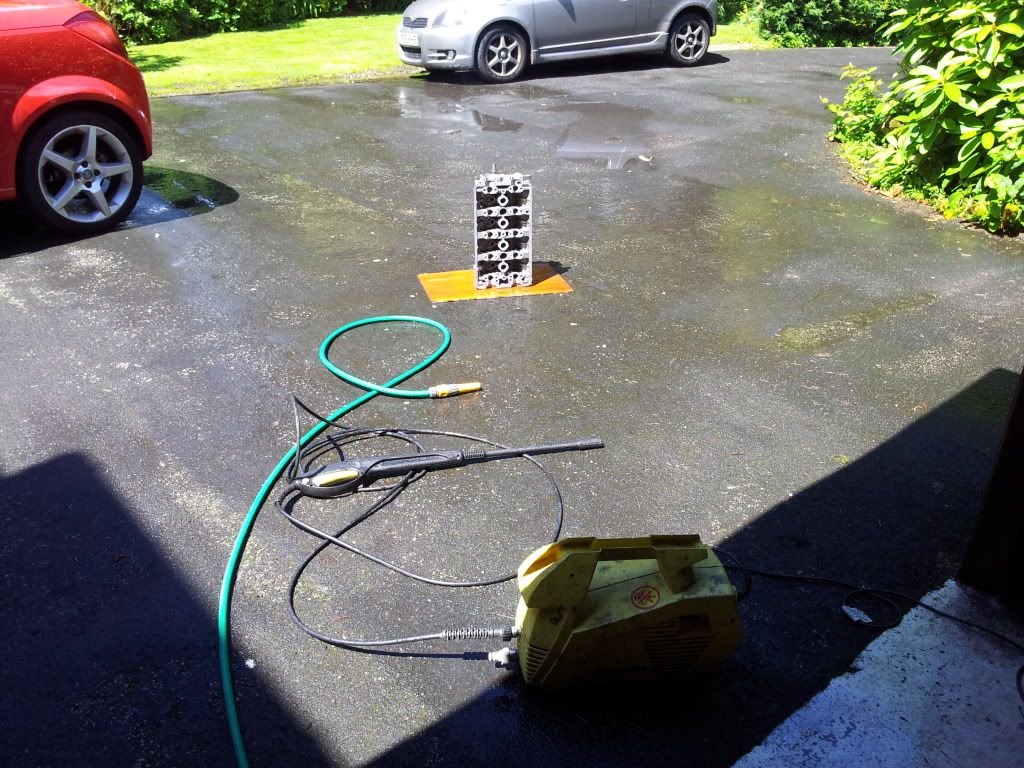

I've spent a good deal of today reassembling the engine again after having to have oil squirter no.4 drilled and tapped . I need to stretch torque the rod bolts down still, but i'll get onto that along with finishing things off with the bottom end on Monday.

This is the sealant what i'm using.

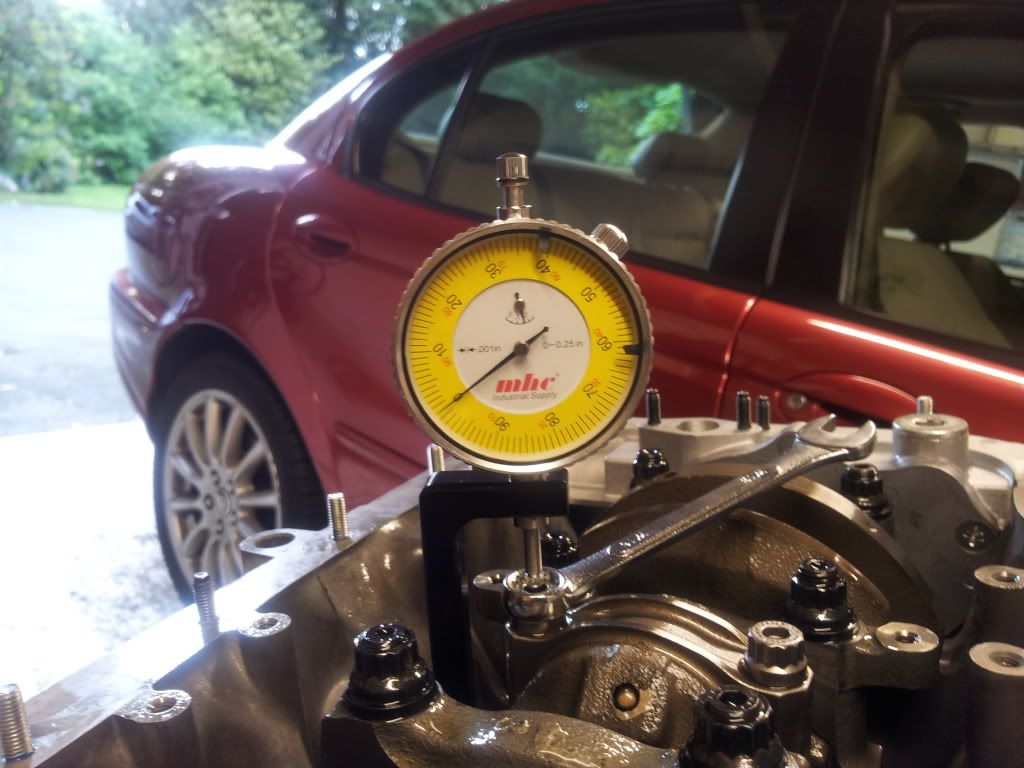

Endyn oil pump.

And a few of where i am at with the block. Note the B&R -10an adapter...

Yeah i know the painting isn't the best on the back...

I've spent a good deal of today reassembling the engine again after having to have oil squirter no.4 drilled and tapped . I need to stretch torque the rod bolts down still, but i'll get onto that along with finishing things off with the bottom end on Monday.

This is the sealant what i'm using.

Endyn oil pump.

And a few of where i am at with the block. Note the B&R -10an adapter...

Yeah i know the painting isn't the best on the back...

Last edited:

is the endyn pump an upgraded one?

is the endyn pump an upgraded one?