RagingAngel

本田 Gearing Authority

- Joined

- Mar 26, 2008

- Messages

- 2,161

English > me...

If you want to turbo get a B20b, lower compression = better for turbo. N/A get a B20z1 but their rare to find.

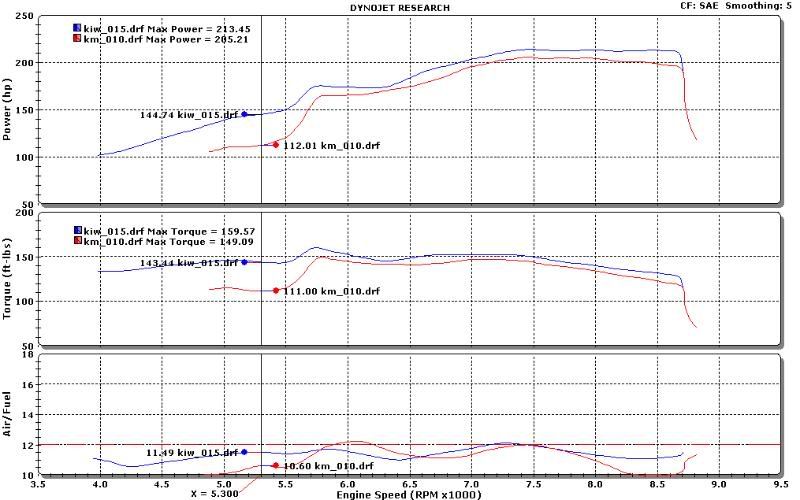

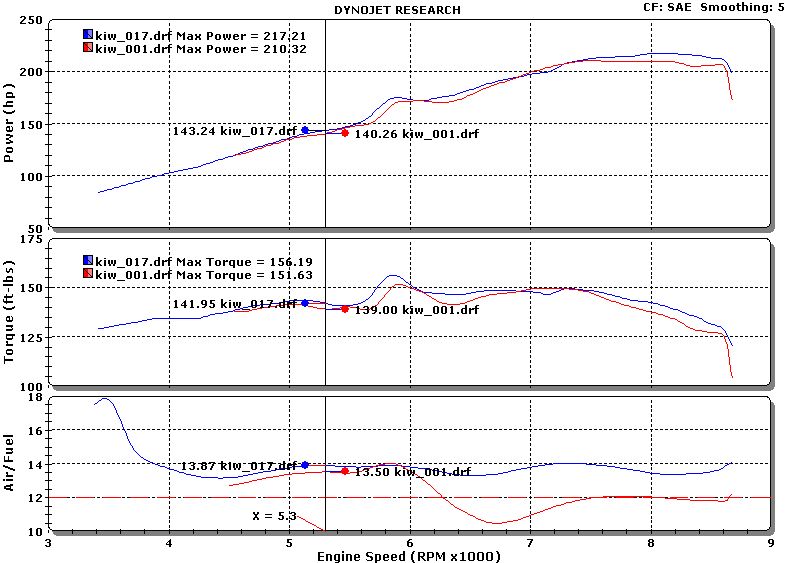

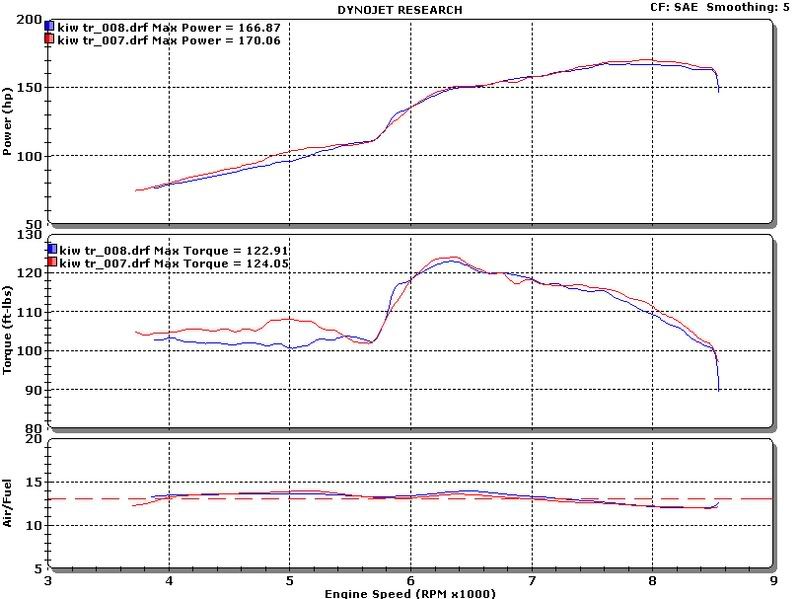

I started with a B16 giving me 160/105,

B16B stroked to 1800 186/128,

B18C1 bored with ITR stroke 193/139,

to B18C1 bored with Ls stroke at 220/160.

JDM motors regardless of year all had the higher compression quoted in the B20Z. It was only in the USDM/CDM (not sure about other markets) where the compression varied. Although the heads on the later model B20s appeared to be the more desirable units, IIRC, they had a larger combustion chamber...at least this is all what I seem to remember when I had an interest in going B20.

Yeah im from the UK. We have the B20b and B20z1. Like in states our compression varies

I can see where your coming from but it would be safer to turbo a B20b but if your gona turbo a B20 anyways you've got to strenthen the block and internal work. The B20b's are cheaper over here and easier to find thats why their more disirable than a B20z1. if your going to be doing internal work get a B20b, no point wasting time and money on something your going to change anyways

A B20 can still be reliable just dont go reving over 7.5K but if your wanting 230whp from a B20 your gona need to strengthen the block, a DC2 gurdle for one. If you want to turbo get a B20b, lower compression = better for turbo. N/A get a B20z1 but their rare to find.

A B18c would require alot less work and hastle to get 230whp and can rev to limiter all day.

With a B20 because of its torque you dont need to drop it down a gear to pull away. With the B18c you have to ring its neck.

Its basically down to your personal choice of where you want your power but 230whp is a gona need a fair bit of spending to achieve

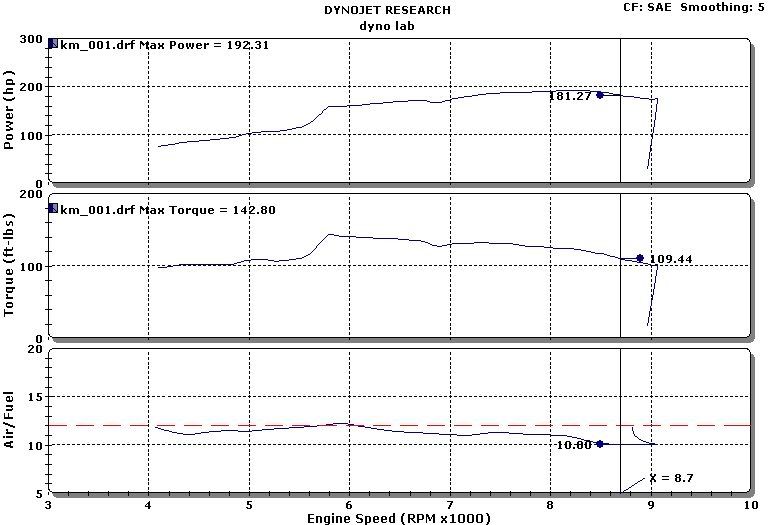

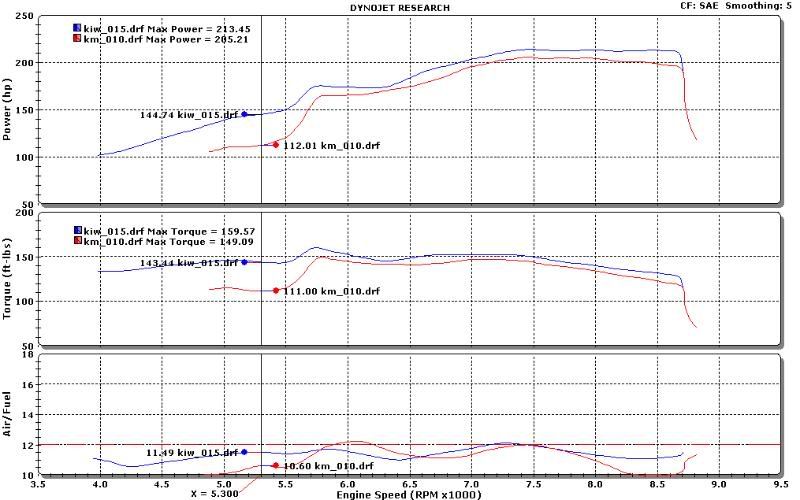

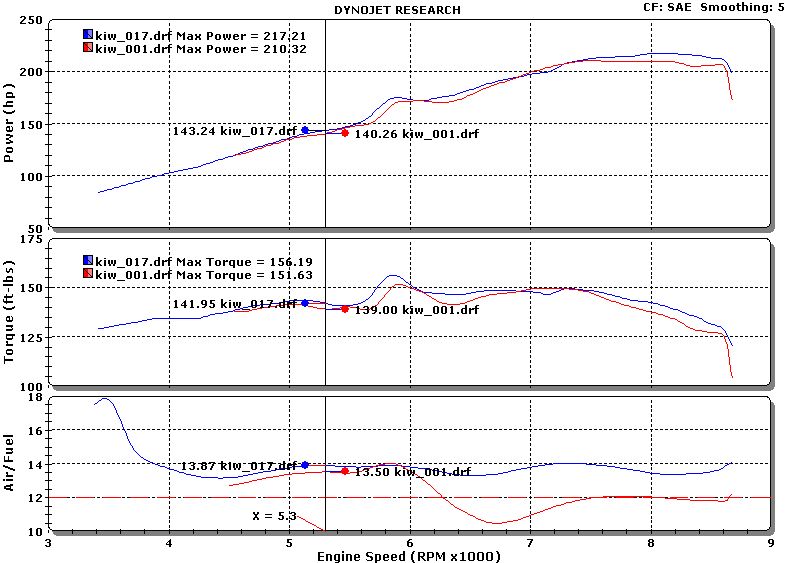

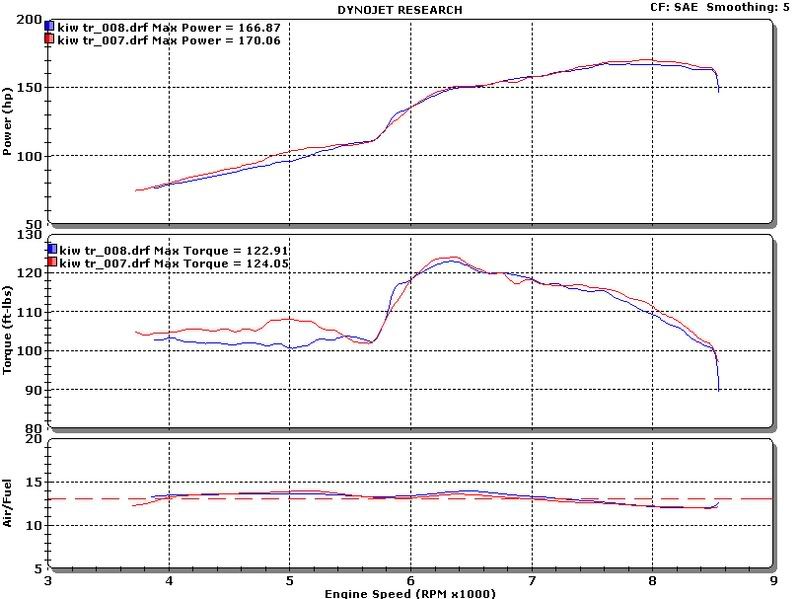

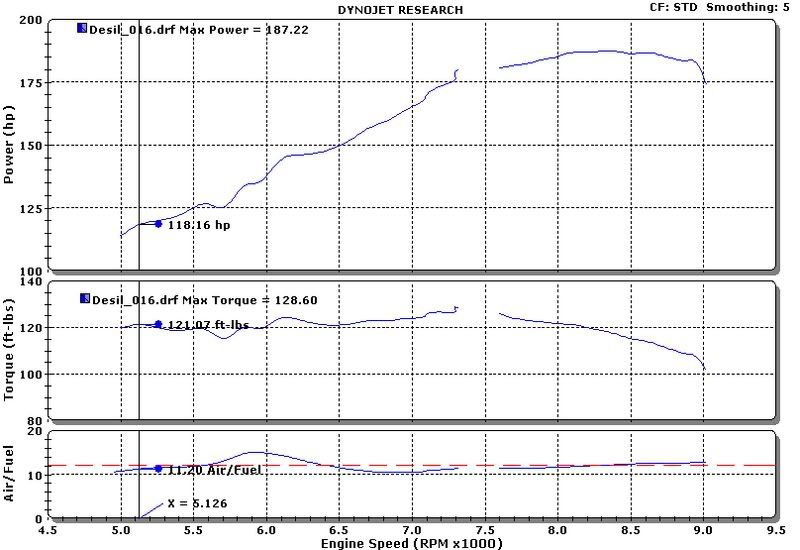

From personal experience, I would go B20 allllll the way. The torque is amazing and addictive. I tried B16b, B16b stroked to 1800, B18C1 bored with ITR stroke, and B18C1 bored with Ls stroke. The last is my current setup and has given me 13.5 times on street tires NA. I started with a B16 giving me 160/105, B16B stroked to 1800 186/128, B18C1 bored with ITR stroke 193/139, to B18C1 bored with Ls stroke at 220/160.

Got dyno charts of all these motors to show? Peak numbers are nice, but I would personally like to see the area under the curve if possible.

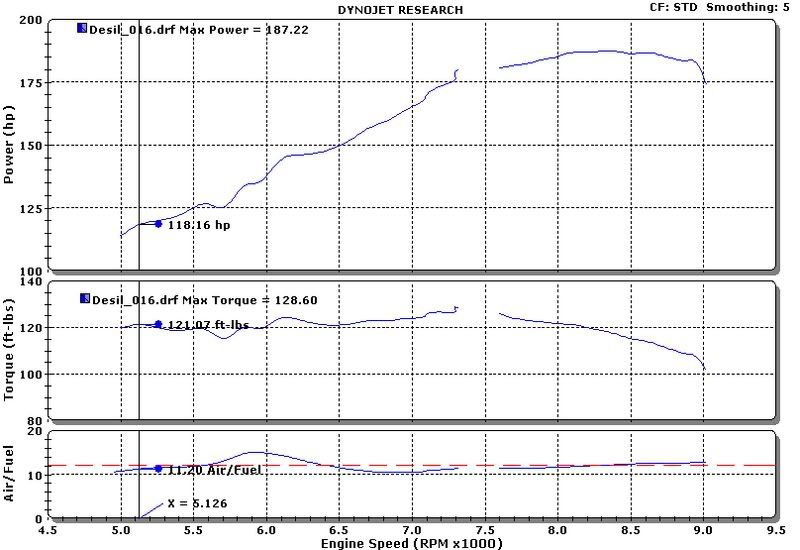

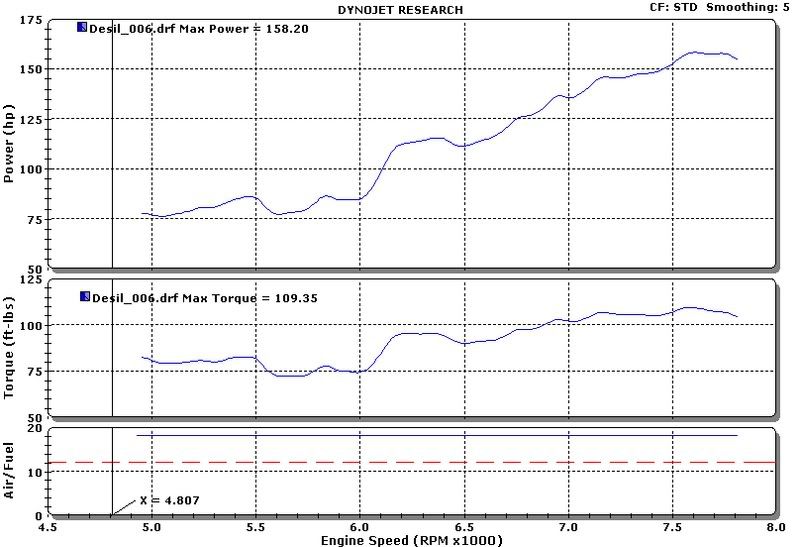

I always have graphs

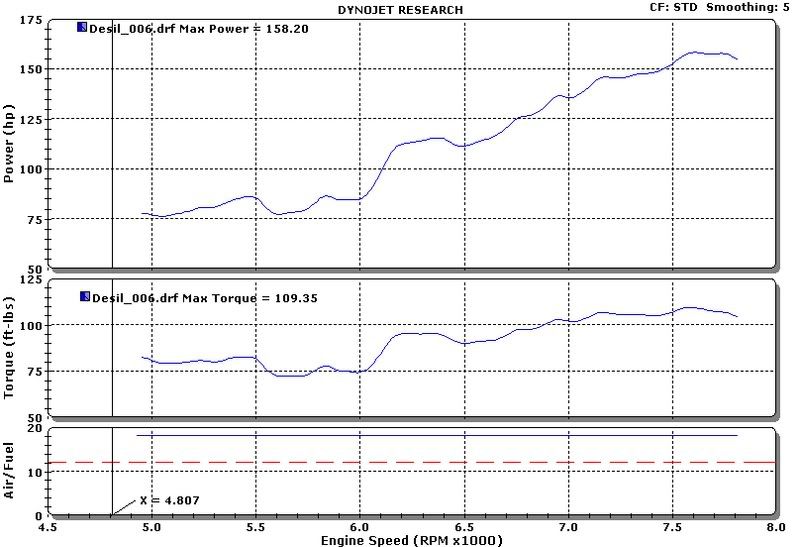

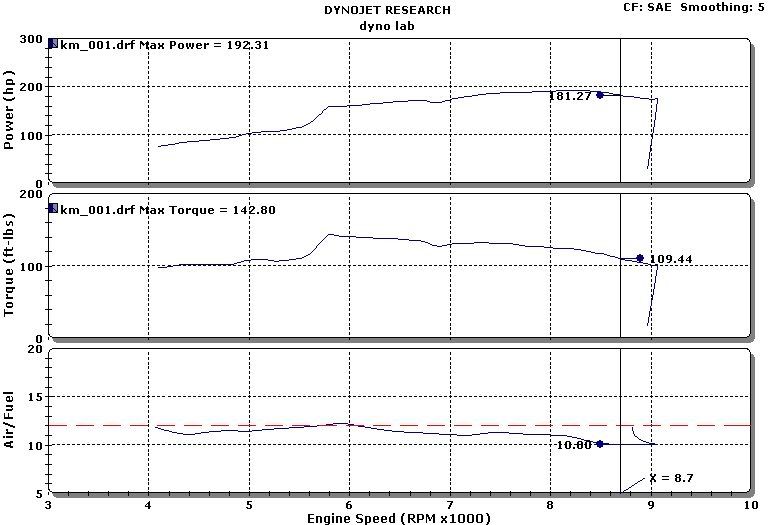

This is one of my old stock Integra Type R.

P2V is not going to be a problem as the Toda A cam is not that big. V2V may be an issue you'd be concerned with (as with any cam for that matter)

if using OEM b20 pistons i think they will hit cause the valve reliefs are small for the non vtec valves. I had this problem when i used non vtec b18a pistons in a b16a block with CTR cams i had p2v contacti ended up enlarging the valve reliefs, replacing 4 bent valves, 3 angle valve job and new seals... problem solved

instead of the b20 stock piston, any piston which is good for this build? Please kindly give me some direction, brand and approx. price please.