You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EK9 Racecar

- Thread starter B16Swt

- Start date

- Joined

- Sep 27, 2015

- Messages

- 1,495

- Car(s)

- Ek9

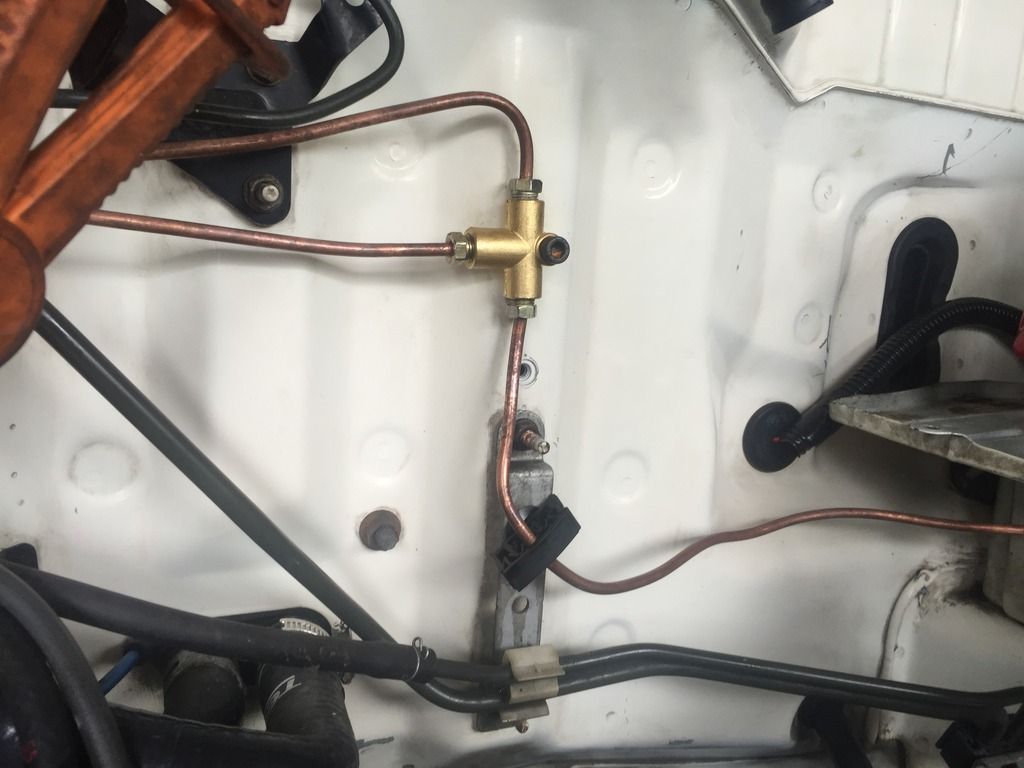

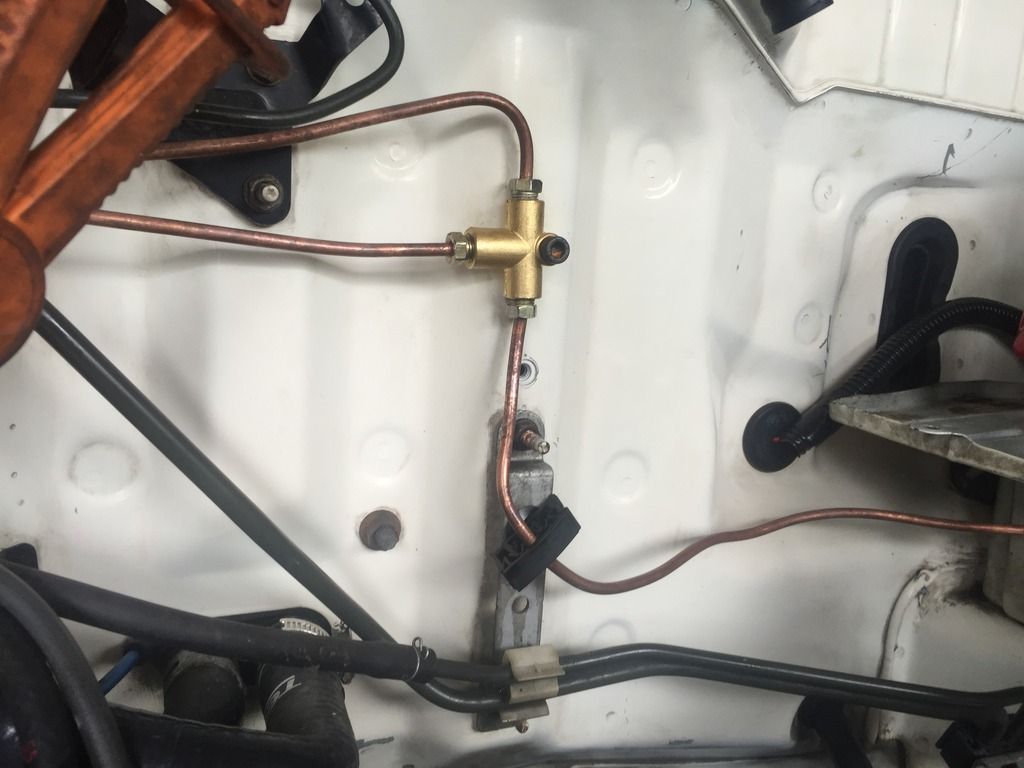

Before I painted the front on the engine bay / front clip I cleaned the bulkhead as best as I could.

It's never going to be a show car but might as well get it as clean as I can I'm going for built for purpose not beauty lol.

I'm going for built for purpose not beauty lol.

Cut off the original rad mounts so I can re attach them to fit the dc2 rad, will borrow the mig one evening after work.

Got to love my Wife).gif) brought me out some cheese on toast for lunch.

brought me out some cheese on toast for lunch.

Some sanding

I did a lot of scraping lol lots of hammerite has been put on and had to come off before I painted.

I'll have to do a second coat of primer, but looks good so far, really pleased considering I hate painting!

It's never going to be a show car but might as well get it as clean as I can

I'm going for built for purpose not beauty lol.

I'm going for built for purpose not beauty lol.

Cut off the original rad mounts so I can re attach them to fit the dc2 rad, will borrow the mig one evening after work.

Got to love my Wife

).gif) brought me out some cheese on toast for lunch.

brought me out some cheese on toast for lunch.

Some sanding

I did a lot of scraping lol lots of hammerite has been put on and had to come off before I painted.

I'll have to do a second coat of primer, but looks good so far, really pleased considering I hate painting!

Jamie_EK9

EK9 K20

- Joined

- Aug 19, 2013

- Messages

- 446

Cheers Jamie

Your bay will look great when done.

I'm keeping a close eye on your thread!

Cheers pal its getting there but the weather this weekend has ground me to a halt

- Joined

- Sep 27, 2015

- Messages

- 1,495

- Car(s)

- Ek9

Car is coming on well sam , top work mate !

Can't wait to see the end result.

Cheers Lee

It's getting there, exciting stuff soon!

- Joined

- Sep 27, 2015

- Messages

- 1,495

- Car(s)

- Ek9

How did you swing that with the misses mate fair play

Coming on well Sam

She's just cool like that

- Joined

- Sep 27, 2015

- Messages

- 1,495

- Car(s)

- Ek9

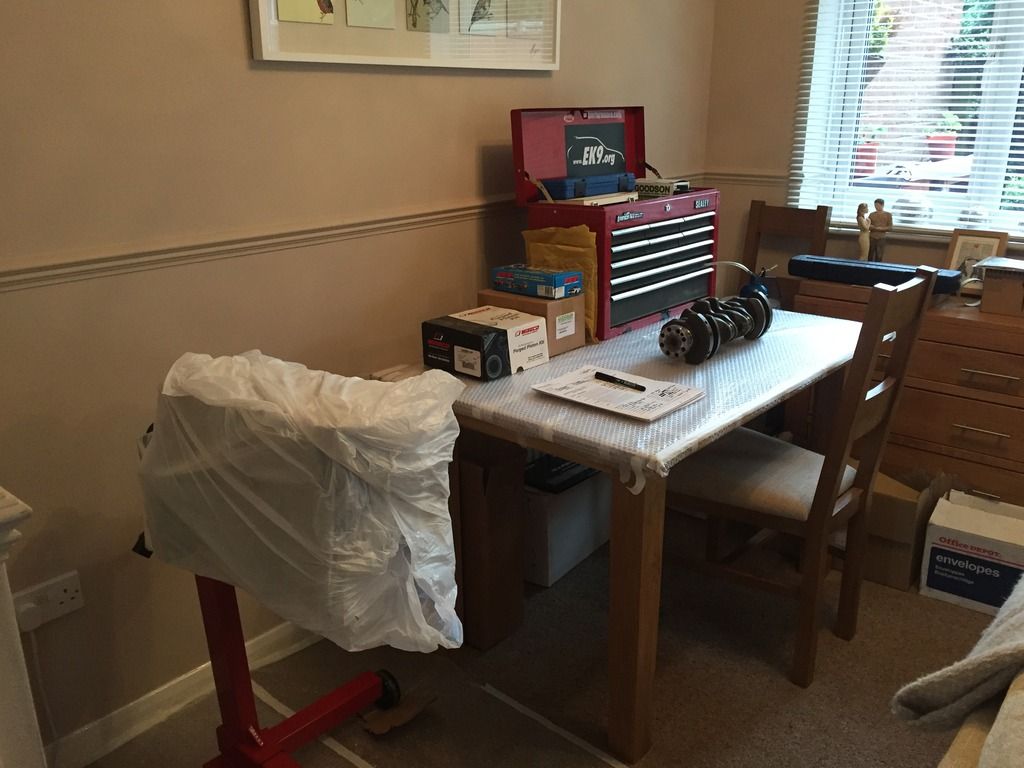

Small update, got some switches for my boost control.

Engine building wise the Pistons have been measured, bores have been measured and piston's have been matched to the bores.

Next I'll be calculating my piston ring gaps, then gapping the rings.

Engine building wise the Pistons have been measured, bores have been measured and piston's have been matched to the bores.

Next I'll be calculating my piston ring gaps, then gapping the rings.

Last edited:

- Joined

- Sep 27, 2015

- Messages

- 1,495

- Car(s)

- Ek9

I've also weighed the Pistons and Rods, I don't know if it's necessary but I think I read somewhere it's a good idea to try and balance the weight of the components evenly.

Luck has it I have 2 rods 1gram heavier and 2 Pistons 1 gram heavier.

So I can match up the heavier Pistons with the lighter rods.

Luck has it I have 2 rods 1gram heavier and 2 Pistons 1 gram heavier.

So I can match up the heavier Pistons with the lighter rods.

- Joined

- Oct 16, 2012

- Messages

- 8,917

You might find there's like 0.5grams between them. My Manley rods came pre weighed and it was points of a gram in it between all four.

I had my rotating assembly balanced, including the weights of the pistons and rods.

I had my rotating assembly balanced, including the weights of the pistons and rods.

- Joined

- Sep 27, 2015

- Messages

- 1,495

- Car(s)

- Ek9

Contacted my machine shop today and they gave me a number for a company that they use for balancing.

So I'm taking the clutch, crank, rods, Pistons and crank pulley and all associated bolts to Bassett down balancing on Saturday morning to get the lot balanced.

Seems sensible to do it, thanks to @jesse888 and @robthedoc for the advice

In the mean time, I've got plenty of engine bay prep to be getting on with while the internals are away.

So I'm taking the clutch, crank, rods, Pistons and crank pulley and all associated bolts to Bassett down balancing on Saturday morning to get the lot balanced.

Seems sensible to do it, thanks to @jesse888 and @robthedoc for the advice

In the mean time, I've got plenty of engine bay prep to be getting on with while the internals are away.