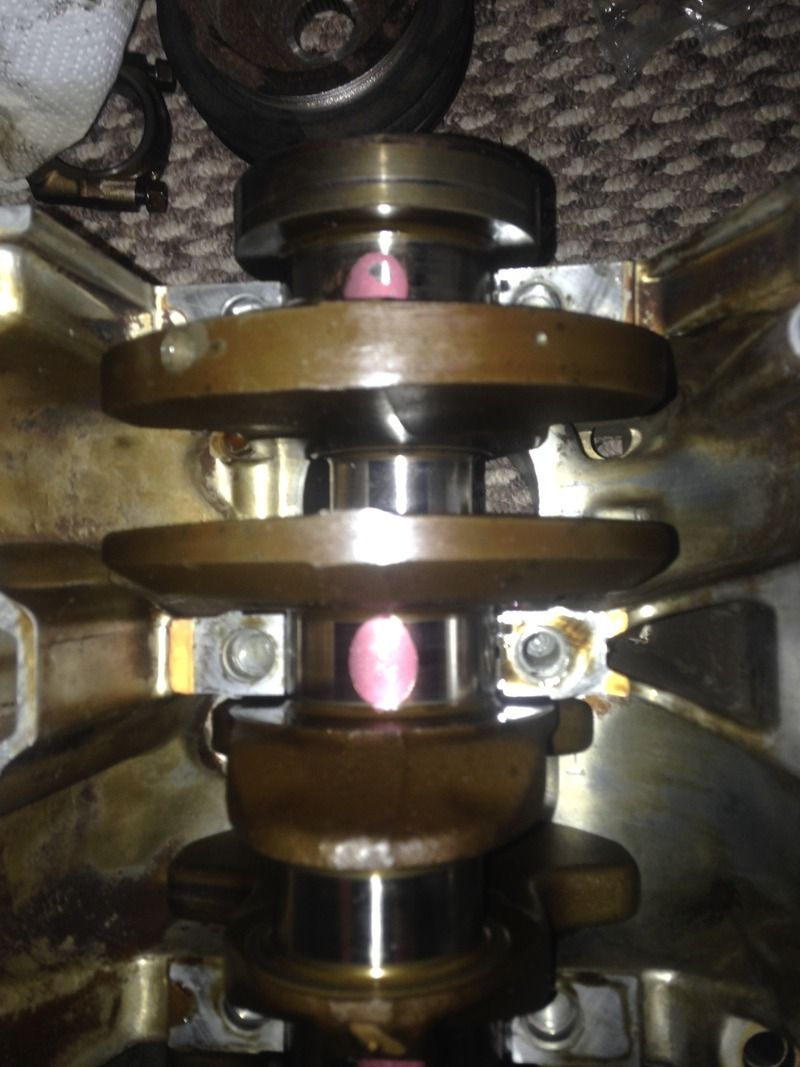

Right I got home tonight and thought I'd start doing the plastigauge sanity check

Started with the rods and didn't get very far...

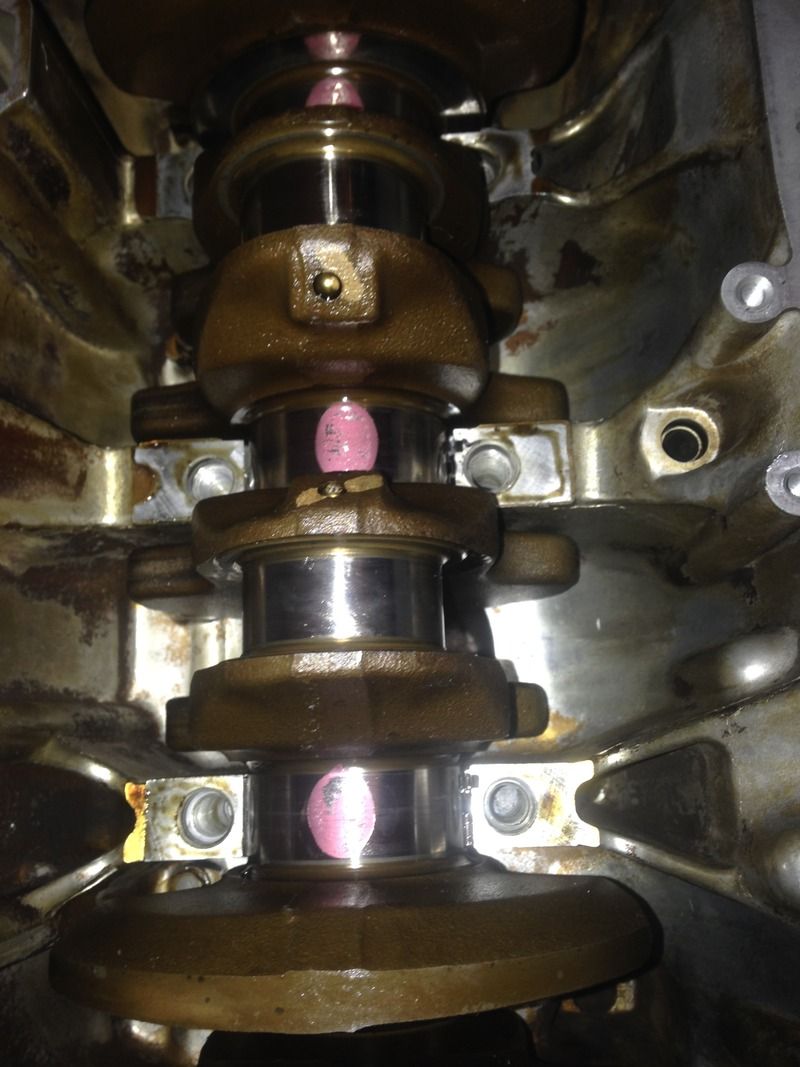

The bearings are ACL race (std size) which from what I gathered were supposed to be fairly loose if anything

The plastigauge I'm using is the green type which as far as I'm aware is spot on

I took my first rod and installed it onto the correct journal (no.4) First torqued the bolts to 15ft lb then 33 ft lb in careful increments. Got these torque specs off the net hope they're right??

When removed the plastigauge is so crushed it's basically fallen apart in the middle and the footprint of it is massive. I tried this rod and bearings on the opposite journal, same again. Like the bearings are massively tight. What the hell is going on, am I doing something wrong?

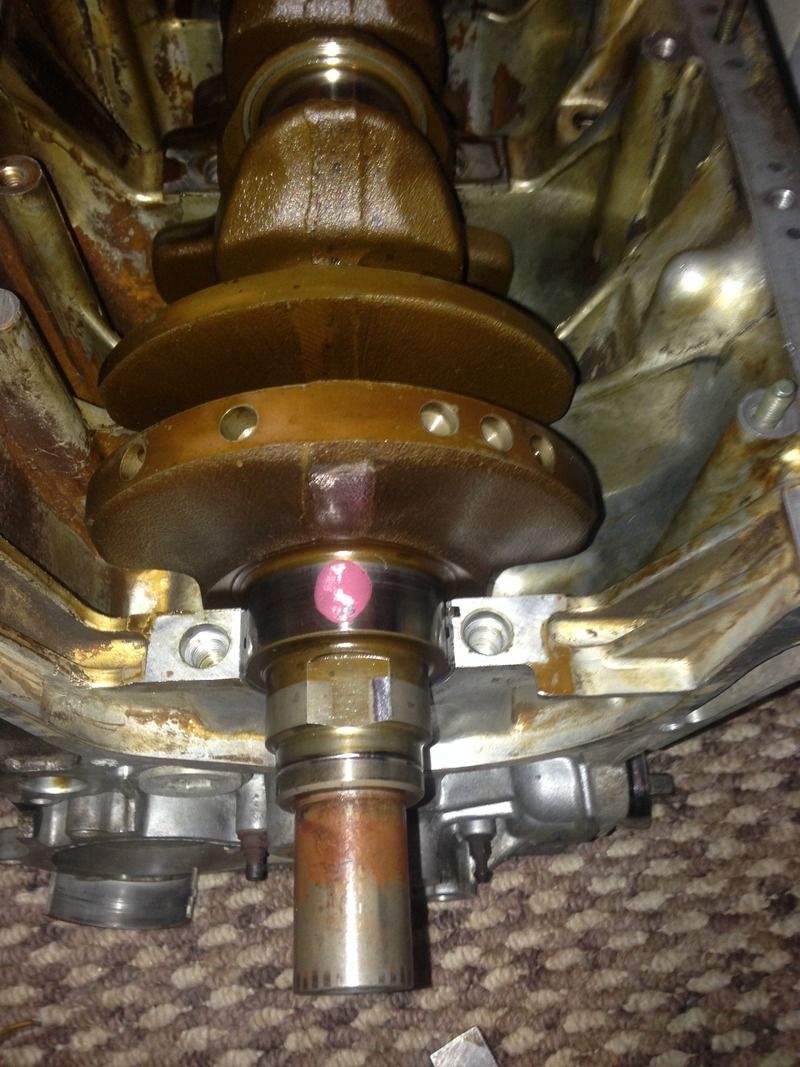

I am doing it with the crank out of the block for the rods but can't see why it would matter...?

Started with the rods and didn't get very far...

The bearings are ACL race (std size) which from what I gathered were supposed to be fairly loose if anything

The plastigauge I'm using is the green type which as far as I'm aware is spot on

I took my first rod and installed it onto the correct journal (no.4) First torqued the bolts to 15ft lb then 33 ft lb in careful increments. Got these torque specs off the net hope they're right??

When removed the plastigauge is so crushed it's basically fallen apart in the middle and the footprint of it is massive. I tried this rod and bearings on the opposite journal, same again. Like the bearings are massively tight. What the hell is going on, am I doing something wrong?

I am doing it with the crank out of the block for the rods but can't see why it would matter...?