You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

K20 DC2 Project,

- Thread starter olly ek9

- Start date

- Joined

- Dec 22, 2007

- Messages

- 2,060

right here is progress so far written by teh owner Justin,,

Well After the teg being off the road with its engine in pieces for nearly a year now I finally decided it was time to sort it out so I can enjoy driving it again.

The car was previously fitted with a Jackson Racing super charger and used to always put a smile on my face with the Vtec on Boost feel!

The reason my engine was broken was a bottom end failure due to bad advice when fitting forged pistons on a previous engine rebuild/upgrade and resulted in a severe scoring to one of the cylinder sleeves (the size of a gudgeon pin!).

This basically meant the bottom end was knackered and needed re sleeving, After doing research I decided the best thing would be a sleeved block from the usa, my next thought was then……If im getting a high spec sleeved block why not go turbo for more power etc !!!!

But after all my research and working out budget costs I have not decided to go down that route because of the simple fact that I would be constantly worrying about reliability and would not be able to afford to do it again.

Honda build there engines to be naturally aspirated so after careful consideration that’s what I wanted to do.

But I couldn’t take a drop in power and go back to a standard Teg so I needed to find a way of at least getting close to what power I had before but staying NA.

So With the help of Olly we decided it would be best with just a standard engine, (well standard internals) but with bolt on mods to try to get the power back near where I wanted to be.

And this build thread below is what we have come up with.

(Works are still on going and all being done at cotley towers by all the elworthys, and a massive thanks to the stump and Sandra for allowing the use of the workshop)

The car arrived at Cotley on a Transporter courtesy of TonyPastie off of this forum Exetertowing

The plans for the powerplant for this car are this beauty !!

This is a K20a engine found in the Newer Integra Type r Models known as the dc5

I bought it complete with gear box, loom gear shift linkage ecu etc. These engines are not like the B engine which is to be removed. The B series engine was Vtec and this K series engine is what they call iVtec where as well as the valve lift being variable the cam timing is also variable. Plus it’s a 2 litre so these are 220bhp standard.

And with this power difference and a few simple bolt on mods i.e. inlet manifold exhaust header etc and a remap they can be tuned to produce 250plus which will certainly make up for the power of the super charger.

So the engine was removed to leave a nice home ready for the K20

Then Olly got to work straight away with the removal of the existing engine mounts and the permanent removal of one mount welded to the chassis leg to make way for the new mounting brackets for the K series engine. These mounts all came in a kit from hasport performance.

A bit of work was needed to get the top of the new mount in under the ABS unit but olly and Joe sorted this between them. Then a touch of primer to cover the bare metal was applied and the mount bracket fitted (Painted red the following day)

And here is where the rear mount adapter bracket went in

It was a case of the actual mounts then being bolted to the engine, which are a nice shiny bit of engineering really!

With all of this done olly and Joe couldn’t resist doing a test fit just to see what it fitted like in the bay

And here’s what it looked like.

This was a good move as it enabled us to suss out what we were going to do for fitting a radiator and other ancillaries.

While the engine was in olly noticed there was a little bit of flex in the rear mount bracket so ash decided he would weld an extra piece to the bracket for strength. WE then removed the engine again so we could inspect the clutch.

While this was out ash worked on the bracket.

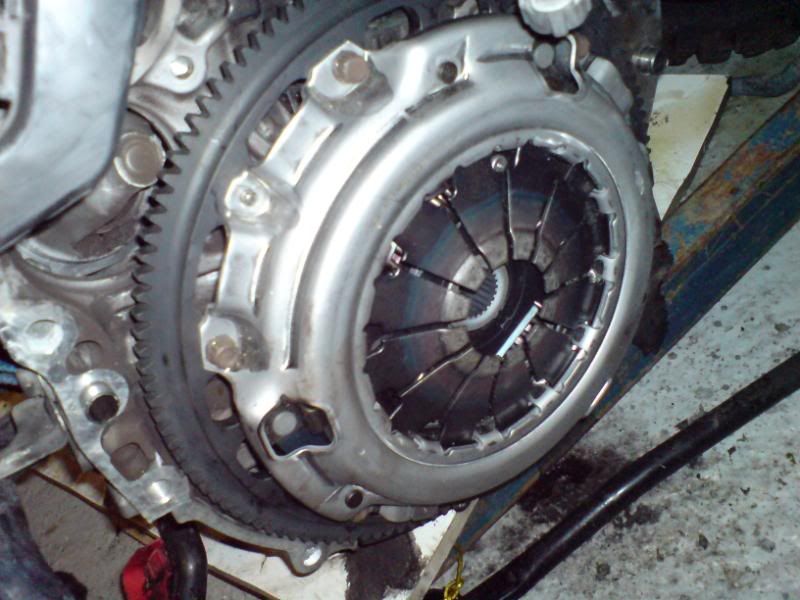

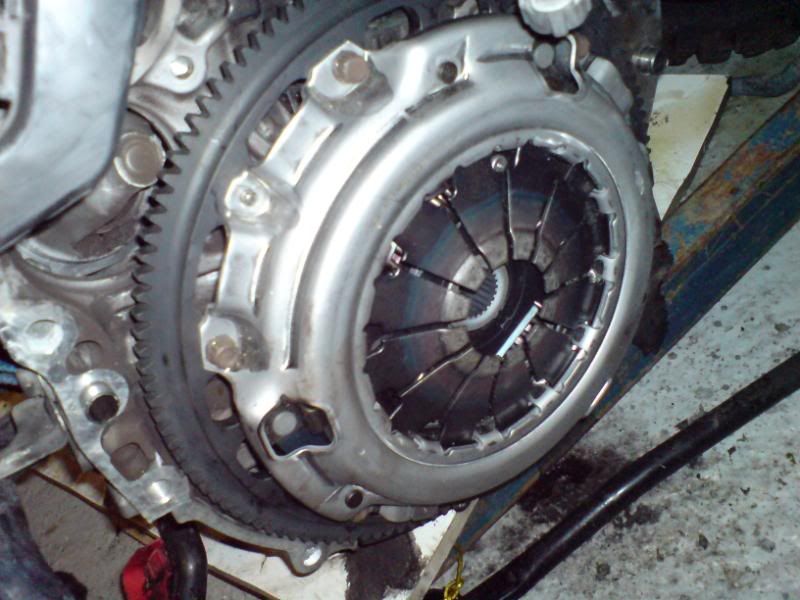

Olly removed the gear box to expose the clutch.

The clutch was fairly worn so a new one was ordered. But while it’s apart surely I should fit a lighter fly wheel!!! So I ordered one of them as well.

It arrived 2 days later so we fitted the new clutch kit and lighter fly wheel.

There’s no point in us fitting the engine back in for the moment incase it needs the exhaust header fitting first and that’s currently some where between the USA and customs at present!

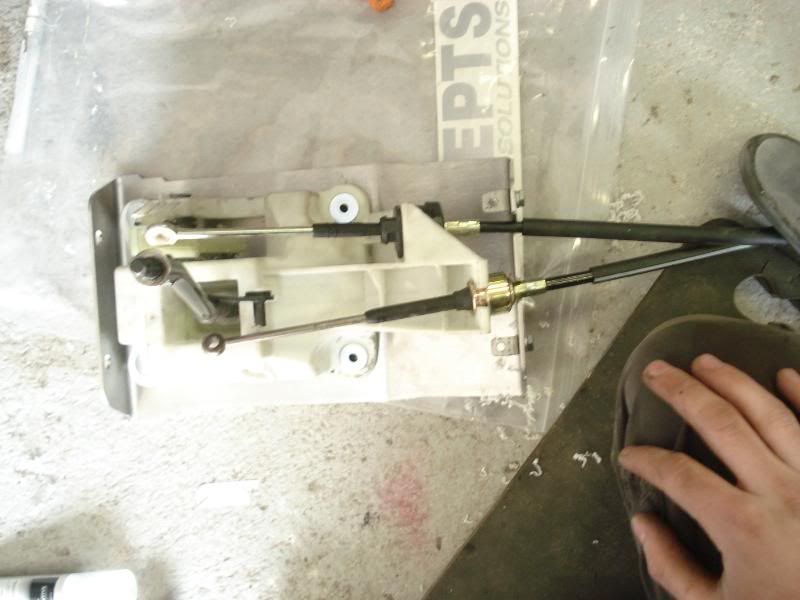

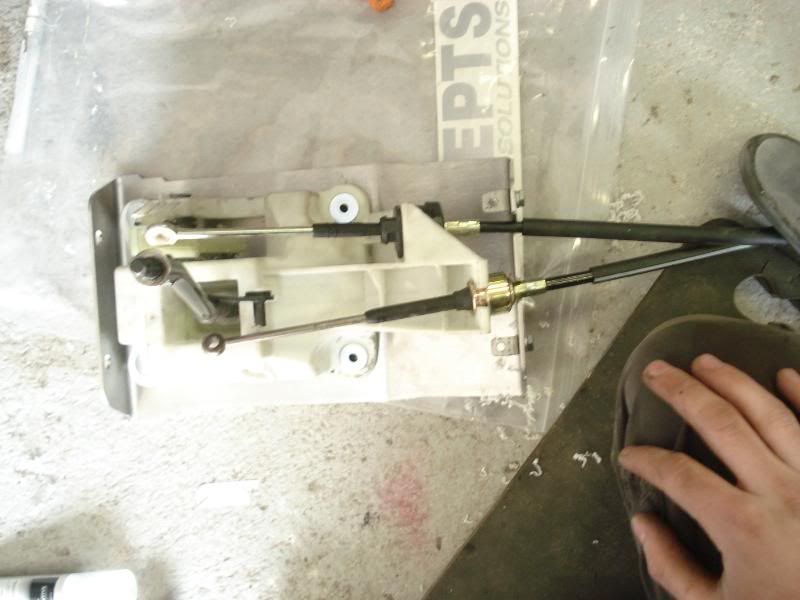

So we decided we would get on with fitting the new gear linkage.

Once again this is different to the b series engine in a few ways mainly being that the box is now positioned on the opposite side of the engine bay as before , its now a cable change box as opposed to a solid rod system and I have a 6th gear now !

So to fit the new linkage we had to fit the shifter box as well and this was done by using a properly manufactured bit of kit by Karcepts.com.

Ash got to work following the instruction from the kit modifying the shifter box and bolting it up to the stainless plate

And then made up circlips etc that were missing from the cables and it looked like this

To mount this is the car the floor pan needed modifying so Joe had already removed all the interior

Allowing olly to fit the template blue peter style and mark the area to be cut out

Then with a careful bit of grinder use and a fire extinguisher at the ready olly proceeded to cut the new hole for the shifter box

Well After the teg being off the road with its engine in pieces for nearly a year now I finally decided it was time to sort it out so I can enjoy driving it again.

The car was previously fitted with a Jackson Racing super charger and used to always put a smile on my face with the Vtec on Boost feel!

The reason my engine was broken was a bottom end failure due to bad advice when fitting forged pistons on a previous engine rebuild/upgrade and resulted in a severe scoring to one of the cylinder sleeves (the size of a gudgeon pin!).

This basically meant the bottom end was knackered and needed re sleeving, After doing research I decided the best thing would be a sleeved block from the usa, my next thought was then……If im getting a high spec sleeved block why not go turbo for more power etc !!!!

But after all my research and working out budget costs I have not decided to go down that route because of the simple fact that I would be constantly worrying about reliability and would not be able to afford to do it again.

Honda build there engines to be naturally aspirated so after careful consideration that’s what I wanted to do.

But I couldn’t take a drop in power and go back to a standard Teg so I needed to find a way of at least getting close to what power I had before but staying NA.

So With the help of Olly we decided it would be best with just a standard engine, (well standard internals) but with bolt on mods to try to get the power back near where I wanted to be.

And this build thread below is what we have come up with.

(Works are still on going and all being done at cotley towers by all the elworthys, and a massive thanks to the stump and Sandra for allowing the use of the workshop)

The car arrived at Cotley on a Transporter courtesy of TonyPastie off of this forum Exetertowing

The plans for the powerplant for this car are this beauty !!

This is a K20a engine found in the Newer Integra Type r Models known as the dc5

I bought it complete with gear box, loom gear shift linkage ecu etc. These engines are not like the B engine which is to be removed. The B series engine was Vtec and this K series engine is what they call iVtec where as well as the valve lift being variable the cam timing is also variable. Plus it’s a 2 litre so these are 220bhp standard.

And with this power difference and a few simple bolt on mods i.e. inlet manifold exhaust header etc and a remap they can be tuned to produce 250plus which will certainly make up for the power of the super charger.

So the engine was removed to leave a nice home ready for the K20

Then Olly got to work straight away with the removal of the existing engine mounts and the permanent removal of one mount welded to the chassis leg to make way for the new mounting brackets for the K series engine. These mounts all came in a kit from hasport performance.

A bit of work was needed to get the top of the new mount in under the ABS unit but olly and Joe sorted this between them. Then a touch of primer to cover the bare metal was applied and the mount bracket fitted (Painted red the following day)

And here is where the rear mount adapter bracket went in

It was a case of the actual mounts then being bolted to the engine, which are a nice shiny bit of engineering really!

With all of this done olly and Joe couldn’t resist doing a test fit just to see what it fitted like in the bay

And here’s what it looked like.

This was a good move as it enabled us to suss out what we were going to do for fitting a radiator and other ancillaries.

While the engine was in olly noticed there was a little bit of flex in the rear mount bracket so ash decided he would weld an extra piece to the bracket for strength. WE then removed the engine again so we could inspect the clutch.

While this was out ash worked on the bracket.

Olly removed the gear box to expose the clutch.

The clutch was fairly worn so a new one was ordered. But while it’s apart surely I should fit a lighter fly wheel!!! So I ordered one of them as well.

It arrived 2 days later so we fitted the new clutch kit and lighter fly wheel.

There’s no point in us fitting the engine back in for the moment incase it needs the exhaust header fitting first and that’s currently some where between the USA and customs at present!

So we decided we would get on with fitting the new gear linkage.

Once again this is different to the b series engine in a few ways mainly being that the box is now positioned on the opposite side of the engine bay as before , its now a cable change box as opposed to a solid rod system and I have a 6th gear now !

So to fit the new linkage we had to fit the shifter box as well and this was done by using a properly manufactured bit of kit by Karcepts.com.

Ash got to work following the instruction from the kit modifying the shifter box and bolting it up to the stainless plate

And then made up circlips etc that were missing from the cables and it looked like this

To mount this is the car the floor pan needed modifying so Joe had already removed all the interior

Allowing olly to fit the template blue peter style and mark the area to be cut out

Then with a careful bit of grinder use and a fire extinguisher at the ready olly proceeded to cut the new hole for the shifter box

- Joined

- Dec 22, 2007

- Messages

- 2,060

Cut out and primed

I then got under the car and removed the b section of the exhaust to make mounting the shifter box easier and also so we can later modify it when the new header is fitted.

It was then inserted back up through the new hole and bolted into place

This is what it looks like from under the car after I had put sealant around it

This left the linkage ready for connecting to the box when all fitted

We are yet to see how the exhaust route will go so may yet have to get some heat reflective matting to protect the linkage cables

Joe then got to action re fitting all the interior and even cleaned the seats for me after as well (thanks Joe) and to be honest the shifter still looks factory

We couldn’t really do much more on the car then as it required the engine being in so we started with the mods.

I bought an RBC inlet manifold which is from the Honda accord euro r which is a really good mod for the standard K20 inlet. This needed to be trimmed down in order to fit as it has a bit on it which is not required for the k20 as its allready on the throttle body.

So olly got the grinder out again with a sanding pad on and we proceeded to fill the workshop up with aluminum fillings.

It then shaped up nicely like so

But I also have bought a larger 70mm throttle body to go on so we marked that out for enlargement as well.

This is about as far as we have got for now but I will keep the thread updated as we progress, Still have the exhaust and hi flow cat to do, wiring harness to be adapted, ecu fitting, radiator arrangement, clutch hydraulics fuel system, air intake etc.

But once again a massive thanks to Olly Joe and Ash

in summary wiring sorted by justin, engine back in and all mounts adjusted by olly and ash, power steering pipe sorted, inlet manifold ported to match new large throttle body, rad fans swapped round so original radiator can be used, few otehr bits i have forgotten!! hahaha :shock:

Last edited:

- Joined

- Dec 22, 2007

- Messages

- 2,060

yep hopefully all ready for japfest and it will be being campaigned by Justin and my brother nathan, my bro joe will also be on track in his dc2 and me in teh ek9,, we have lots of sessions throughout the day so keep an eye out for us!!

Accessory Zone

New Member

- Joined

- Jul 6, 2007

- Messages

- 626

Good thread there. Nice work. Not seen one put in a dc2 before that looks really good.

blinx9900

Super Moderator

- Joined

- Dec 5, 2006

- Messages

- 10,880

very impressive!! what engine mods you gonna do? i STRONGLY suggest a quality header,2.75" exhaust, velocity stack intake, cams, and KPRO or aem ems. my friend has that setup and hes making 260bhp!! be careful getting used to the shifter though, that setup is known from shifting from 5th to 2nd on accident!! and backwards too from 2nd to fifth, i know 2 people that blew up there K that way

- Joined

- Dec 22, 2007

- Messages

- 2,060

we are doing rbc inlet manifold 70mm throttle body, race header, car is running hks silent high power exhaust and i have got to cut in teh sports cat somewhere hen teh manifold arrives, car will be booked in with TDI north for remap on K pro,, its amazing how much flexibility you have in teh mapping with I vtec,, need to sort out the air filter etc yet,, we have an old AEM form teh dc2 B series i was thinking of modding for teh time being,, any reccomendations!??!

blinx9900

Super Moderator

- Joined

- Dec 5, 2006

- Messages

- 10,880

for intake use a veloicty stack with a 3" pipe and filter, you can see the info in this thread i made a while back, it has links and tells you which filter fits and all:

http://www.ek9.org/forum/air-intake...ntake-thread-intake-really-best-i-answer.html

i have not heard of the HKS silent power exhuast, if its 60mm i think it will be too small, but if your going to run a cat it dosent really matter as that will be the primary restriction.

http://www.ek9.org/forum/air-intake...ntake-thread-intake-really-best-i-answer.html

i have not heard of the HKS silent power exhuast, if its 60mm i think it will be too small, but if your going to run a cat it dosent really matter as that will be the primary restriction.

- Joined

- Dec 22, 2007

- Messages

- 2,060

we used the engine loom from the k20 engine and fed it through down to the position of the ecu.( simply removed original ecu and mounted k series ecu in its position )

then the rest was made easy with the hybrid racing harness available through karcepts.com which ran behind the dash and picked up another part of the loom to run the clocks etc.

its really simple to do as it comes with an idiots guide how to cd aswell.

check out there site , Karcepts Engineered Solutions - Home.

then the rest was made easy with the hybrid racing harness available through karcepts.com which ran behind the dash and picked up another part of the loom to run the clocks etc.

its really simple to do as it comes with an idiots guide how to cd aswell.

check out there site , Karcepts Engineered Solutions - Home.

- Joined

- Dec 22, 2007

- Messages

- 2,060

bdl 70mm throttlebody, karcepts mountingplate and hand ported RBC inlet manifold all bolted together, just waiting on header still, AEM fuel rail and custom aluminum radiator + slimline fans so we can get going on teh project again,,

Last edited:

nice! you already have the most difficult part to get!

nice! you already have the most difficult part to get! excellent progress

excellent progress

looking good! thanks for sharing!

looking good! thanks for sharing!